AEP transducers boasts a well-established presence on the market for the designing, the manufacture and the production of: strain gauge sensors, electronic instrumentation and application software.

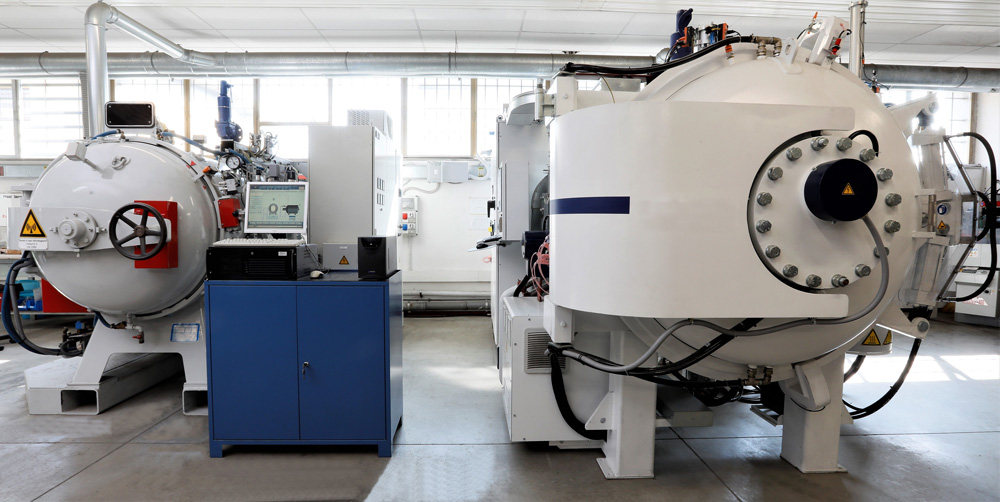

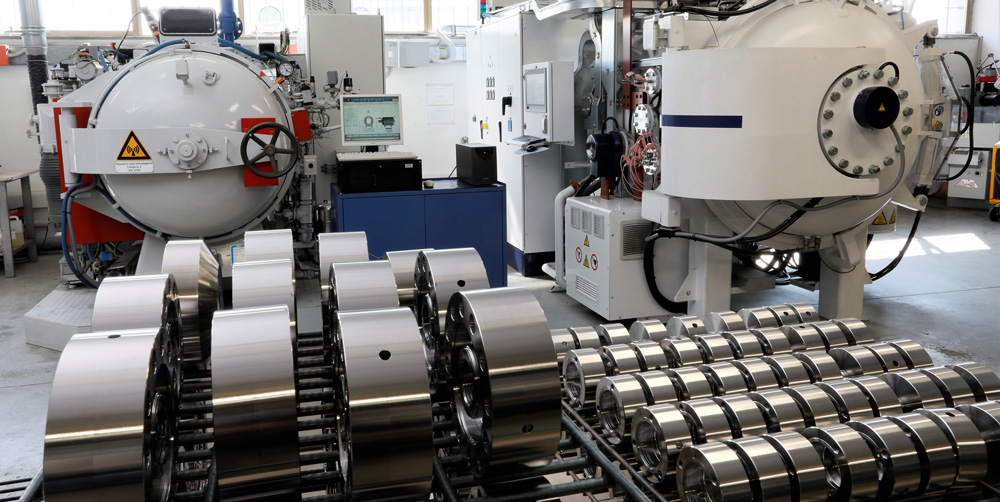

Production plant of over 3000 m2.

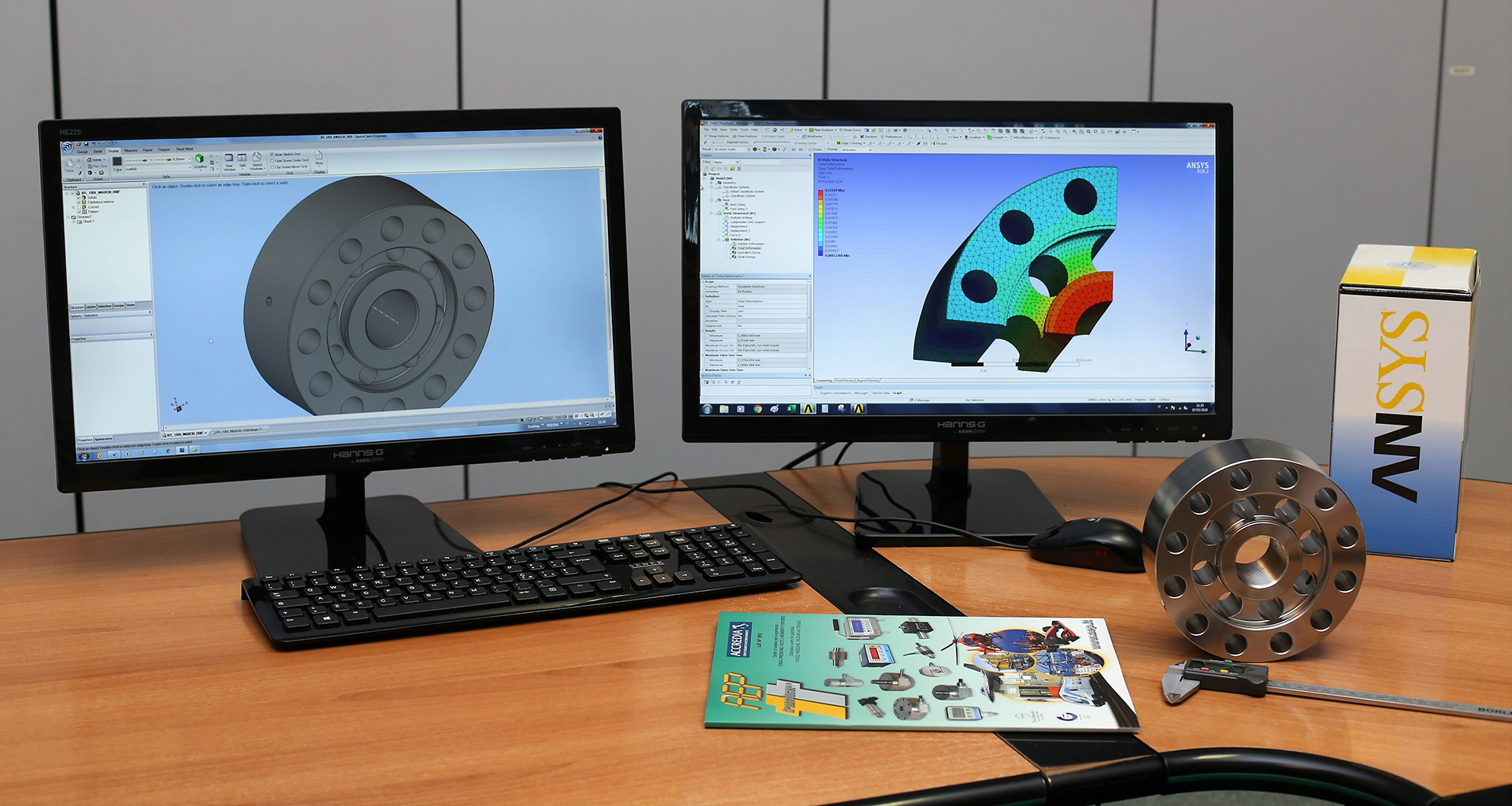

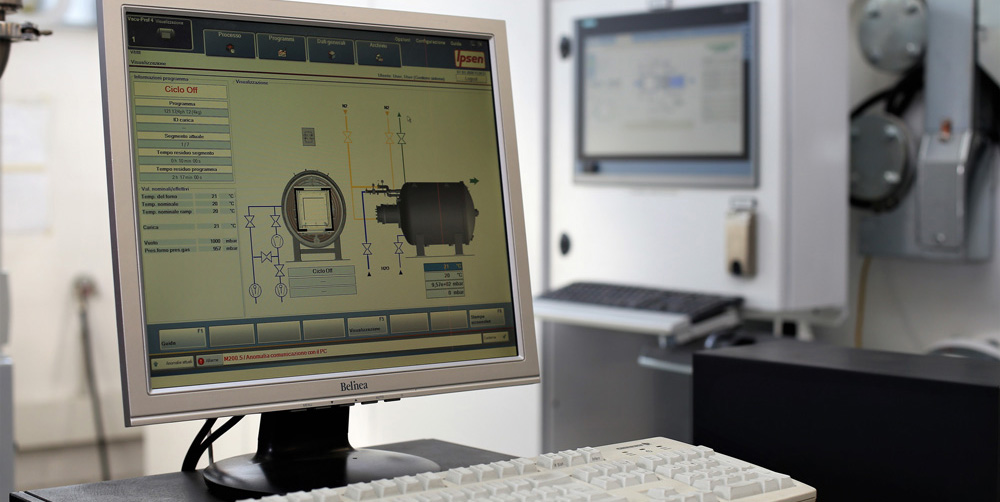

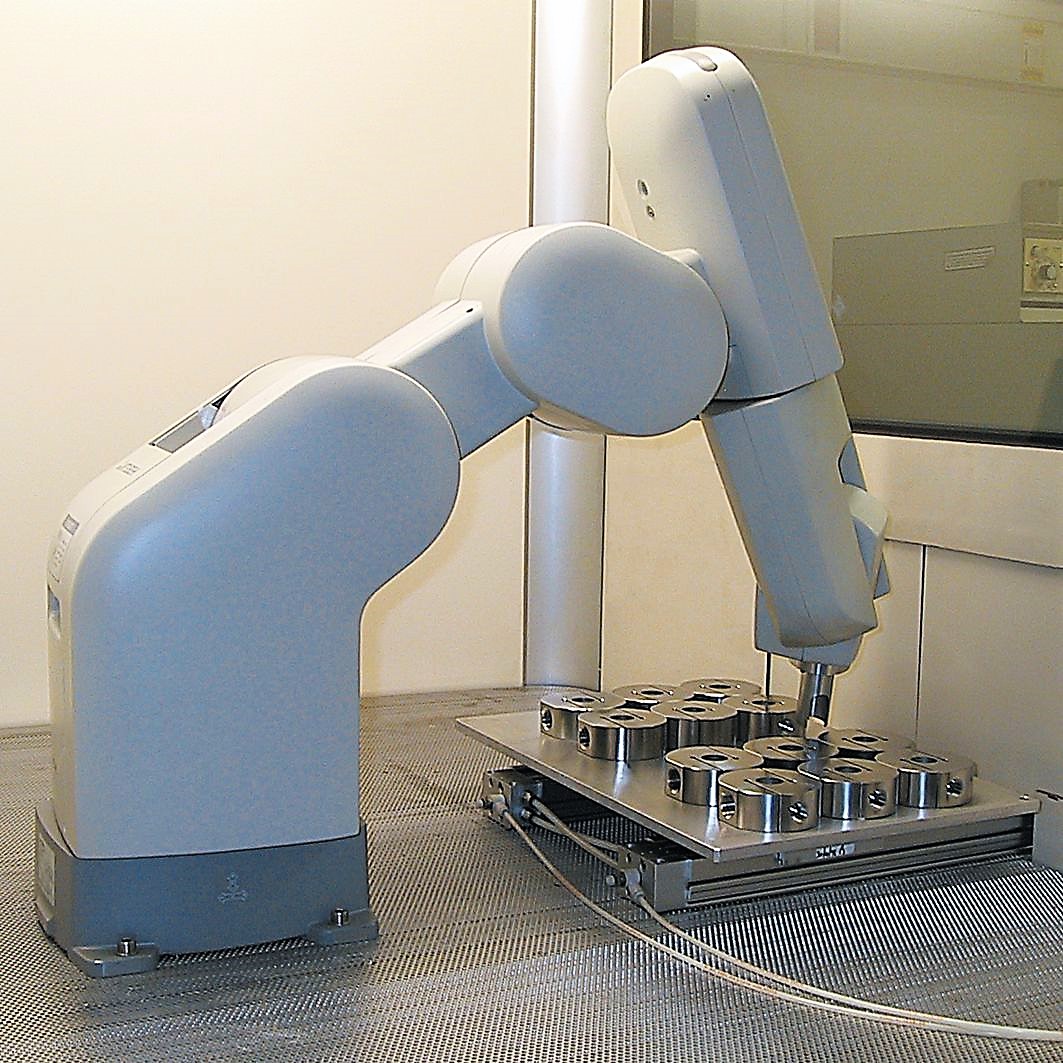

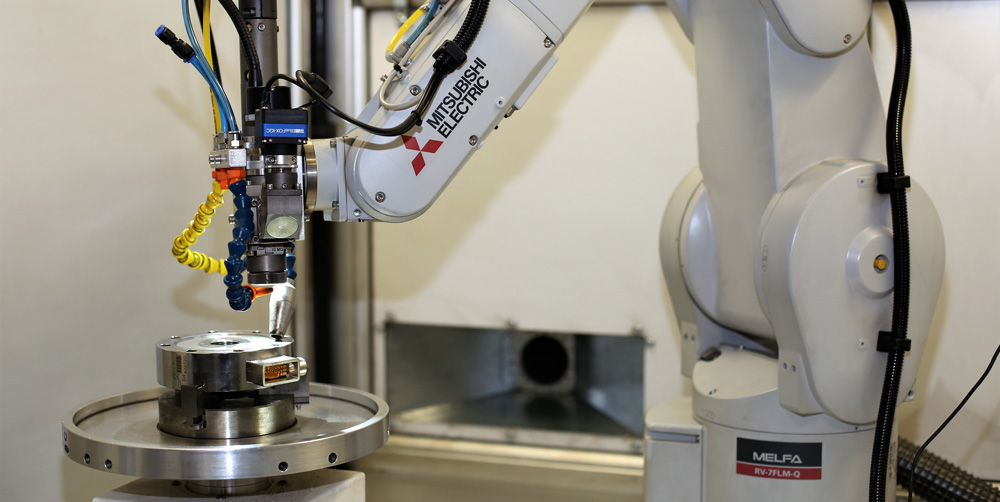

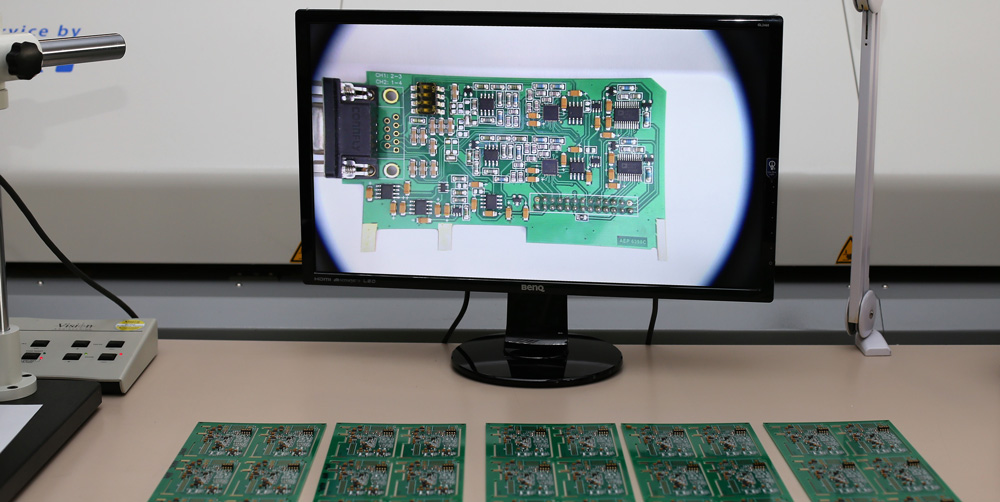

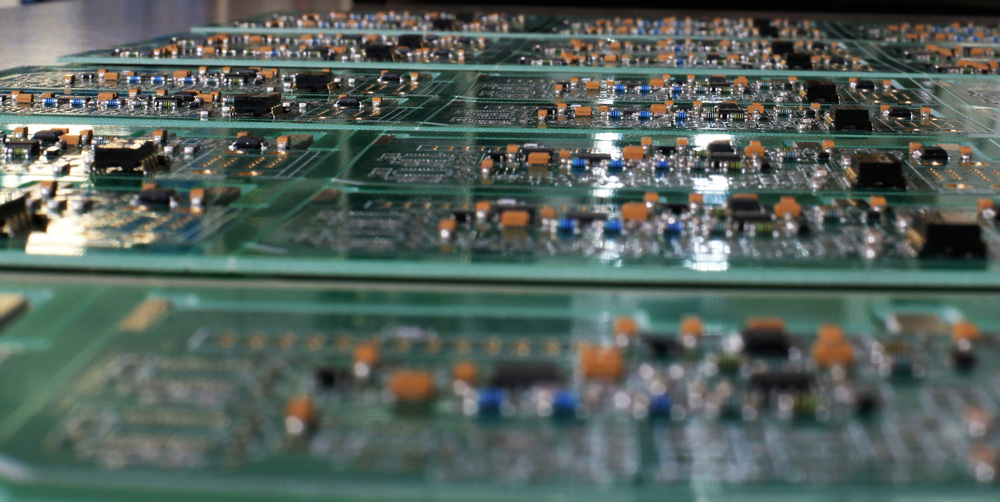

In order to maintain an increasingly important and competitive presence, even on international markets, the Company in recent years has dedicated most of its investments to an increasingly advanced automation of the various production cycles, and in particular everything that can promote an ever better quality price ratio of its products.

All the parameters of the sensors during the production process are stored on our data base to guarantee the traceability of all the information even after 20 years.

ELECTRONIC WEIGHING AND DOSING

WEIGHING ON LIFTING SYSTEM

WEIGHING IN ATEX ENVIRONMENTS

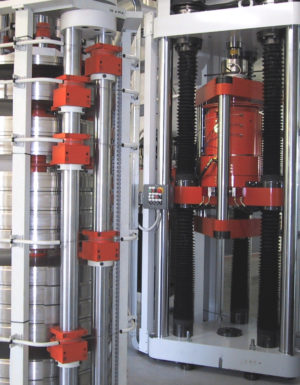

FORCE STANDARD MACHINES

MATERIALS TESTING MACHINES

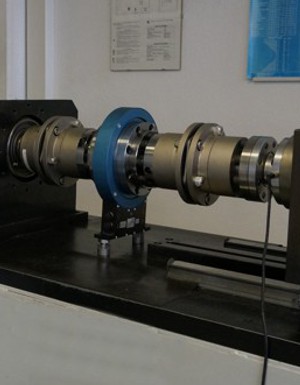

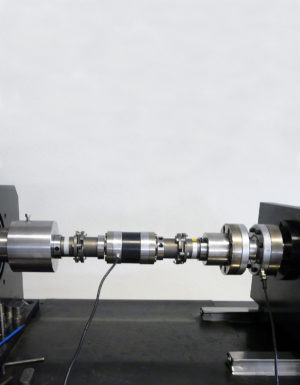

TEST BENCHES

AUTOMATION

RESEARCH LABORATORIES

CALIBRATION LABORATORIES

TEST LABORATORIES

HYDRAULIC SYSTEM

OLEODYNAMIC SYSTEM

PNEUMATIC SYSTEM

AUTOMOTIVE APPLICATIONS