Force transducer suitable for material testing machines and test benches in general.

High mechanical resistance.

Completely made of stainless steel.

Completely LASER welded.

Degree of protection IP67.

Long term stability.

On request ATEX certificate (Zones 1 and 21) GAS and DUST

ACCESSORIES

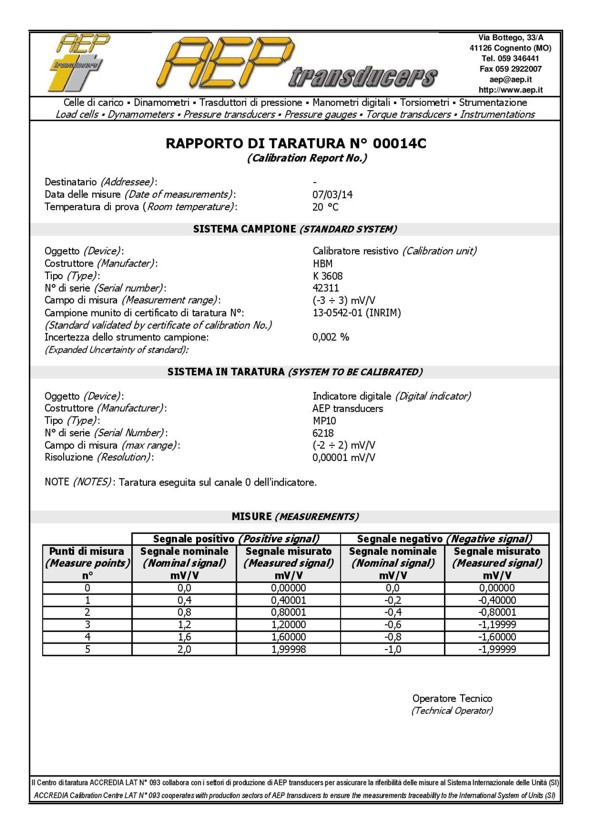

Calibration Report COMPRESSION

Calibration Report TENSION

ACCREDIA certificate COMPRESSION

ACCREDIA certificate TENSION

ACCREDIA certificate BIDIRECTIONAL

Per applicazioni in TRAZIONE:

n. 2 snodi sferici (ACCEM)