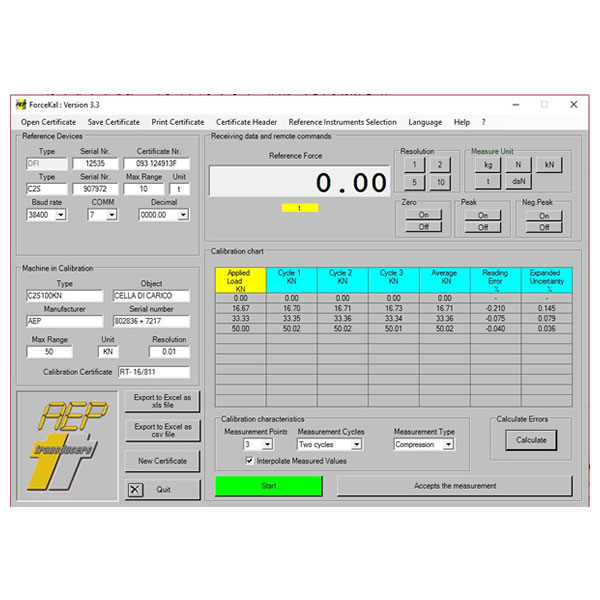

The programme is designed to perform calibration of material testing machines, force testing machines, test benches or other equipment using sample devices.

The assessment of the calibration uncertainty is carried out in accordance with the requirements of ENV 13005 and Appendix D of ISO/DIS 7500-1.

To carry out the calibration it is necessary to generate a significant number of measurements (5, 8 or 10) of increasing forces over two or three measurement cycles to verify the repeatability of the machine being calibrated.

At the end of each cycle of increasing measurements, the machine must be reset to zero before performing the next cycle of measurements.

At the end of the test, the program calculates:

a) the mean of the readings

b) the Reading Error %

c) the Extended Uncertainty % associated with each measurement point.

All certificates are then printed and stored in a database, allowing the history of the calibrations performed to be maintained.

ACCESSORIES

See instrumentation and connection cables